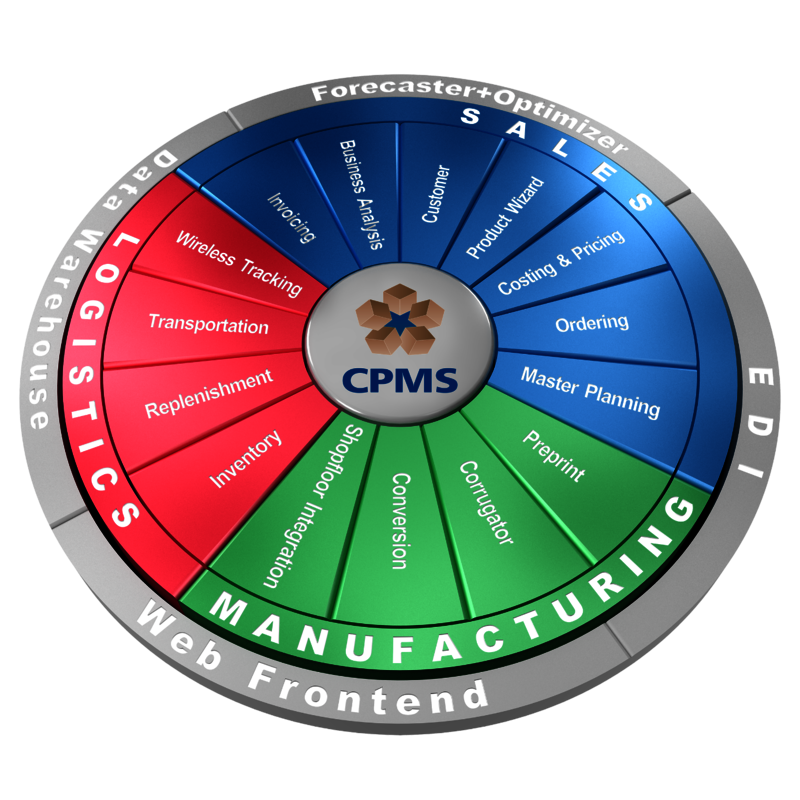

CPMS is the solution for the corrugated board industry

CPMS stands for Corrugated Packaging Management System and is the business application for the corrugated industry worldwide. The modular software now supports 250 corrugated plants from the customer’s inquiry, through production, to invoicing. The basis for this wide product range was WITRON’s involvement in the development of control applications in the industry in the 1980s and 1990s. The first control centers and planning systems with industry-specific focus were developed on the basis of this competence. The first WITRON MES applications were amended by extensive functionalities for sales and shipping. CPMS from WITRON thus digitally maps the entire value chain of a corrugated plant. Configuration options allow

CPMS to be used in the production of everything from classic transport packaging to multi-part digitally printed point-of-sales displays. Companies with many production sites benefit from the CPMS Multiplant option, which enables centralized capacity control with harmonized data. Today, our customers are faced with new challenges, which we tackle and master together with them. The industry sector as well as many other business areas are increasingly relying on the automation and digitalization of production and logistics processes. CPMS is a future-oriented platform that exchanges extensive process data with machines and partners involved in the supply chain with the aim of overall optimization.

The CPMS Sales Module supports the sales activities of a corrugated plant from product generation (on FEFCO basis or self-defined templates), through quotation and order processing, to delivery note preparation, and invoicing. A customizable CPMS cost calculation and predefined price strategies will allow you to provide customers with individual price information on price lists or quotations, as quickly as possible. Your customer service can use existing quotations and price lists as templates for customer orders and, with the help of functions such as capacity and resource availability checks, promise delivery dates quickly and with a high degree of reliability. Thus, CPMS supports a balanced utilization of your machinery or between manufacturing plants and avoids overload.

The CPMS Manufacturing module contains all functionalities needed for the management, planning, and execution of manufacturing orders (customer or replenishment orders). Once the manufacturing orders have been checked and approved, the corresponding machine jobs are forwarded to the CPMS deckling optimization and conversion machine planning based on the proposed manufacturing routing and delivery date. System-based scheduling then takes place according to customizable optimization targets such as least costs and throughput time, as well as delivery date compliance. The production planner will be supported by a graphical scheduling board and modern scheduling algorithms for machine planning to achieve the best planning results. CPMS allows you to choose between forward and backward planning methods (also known as push or pull planning). The adherence to the promised delivery dates will always be prioritized. All printing technologies such as litho, flexo, and digital printing as pre- or post-print processes are supported.

The CPMS Logistics module includes functionalities for an efficient inventory management as well as transport scheduling, and dispatch processing. All relevant material types such as paper reels, tools, auxiliary materials, as well as semi-finished and finished goods are managed by a standard basic functionality. Material or industry-specific features such as the registration of paper reels at the corrugator or the recording of tool usage, etc. supplement the inventory management. CPMS transportation planning provides advanced algorithms for automated creation of deliveries while adhering to defined delivery windows based on electronic road maps. Loading is controlled by RF terminals, which notify the forklift driver of the loading and create all transport documents based on this information. Customer-focused external warehouses or a central warehouse in the case of multiple locations can be configured in CPMS and allow for industry-specific delivery processes.

The standard version of CPMS is enhanced by the CPMS Multiplant module, which extends all CPMS functionalities to several production sites of a company for a centralized utilization of CPMS functions (national sales organization, cross-plant planning) within a region for mutual benefit. For example, CPMS Multiplant enables the logical centralization of the sales departments for several plants. Customer orders can - with the appropriate authorization of the user - be relocated to port routes. The expected cost differences for a relocation will be displayed to the user in the company’s currency prior to a final decision.

The CPMS modules Sales, Manufacturing, and Logistics form the packaging core of the CPMS application suite. It is connected to other WITRON Add On modules by a Digital Access Layer, which is also the basis for connecting third-party software. Available CPMS Add On modules are: CPMS Data Warehouse: Business data from all areas of the CPMS Packaging Core is made available in a special data structure to allow high-performance access with standard BI tools. CPMS EDI Messages: Customers and partners can exchange data with CPMS bi-directionally via electronic channels. CPMS Forecaster + Optimizer: The add-on module supports forecasting of paper and finished goods requirements. It uses forecasts determined by itself or given by the customer to define optimized batch sizes for replenishment. The optimization is based on total costs and considers restrictions such as capacity and warehouse size. CPMS Mobile App: Mobile browser-based operations are enabled by the CPMS Mobile App, which exchanges data with the Packaging Core. The scope of functions covers areas in sales, manufacturing, and logistics that particularity benefit from this technology.

“We are continuously developing the software.”

We have been optimizing processes in the corrugated board industry for more than 30 years. Our customers include packaging companies such as International Paper, DS Smith, Smurfit Kappa, Dunapack, Stora Enso, Model, the THIMM Group, Delkeskamp Verpackungswerke and many more. With the help of CPMS, all business areas can be consistently integrated into one system. The connection of systems such as financial accounting, CAD, machines, conveyor systems, as well as map material for route scheduling is made possible via the Digital Access Layer. We ensure extensions/improvements through a software maintenance program. We support you with the implementation, the operation, as well as with extension requests

CPMS Onlinetracker

Click here to go to the CPMS Online Tracker