Satisfied customers around the world

Logistics managers worldwide, from different industries use WITRON solutions to optimize their processes, increase the flexibility of their material flows, save costs, relieve the environment and create ergonomic workplaces. Our customers buy a promise: WITRON delivers an optimal material flow, a guaranteed delivery performance and thus added value in logistics. We realize projects in North America, Europe, Asia, and Australia. Well-known companies from trade, industry, and services - corporations and medium-sized companies - entrust us with their logistics processes.

Migros Verteilbetrieb AG Neuendorf: “Flexibility is the match-winner”

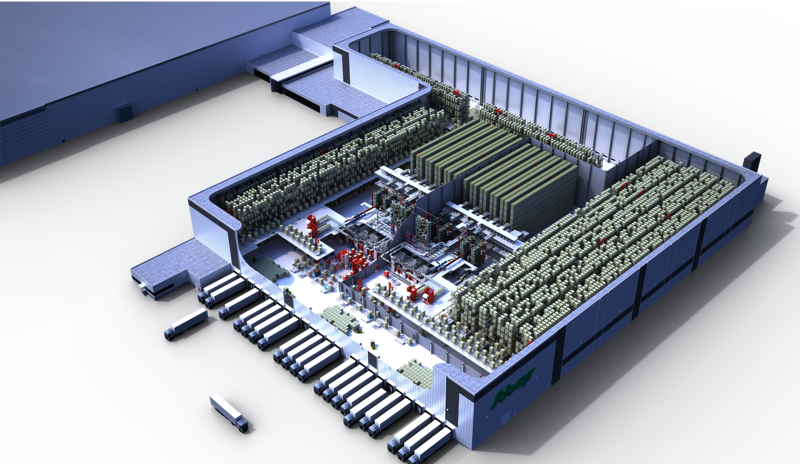

COOP Norway: 30 percent more throughput during ongoing operations

Asko builds new fresh food warehouse

Podcast: Flexibility is the match-winner

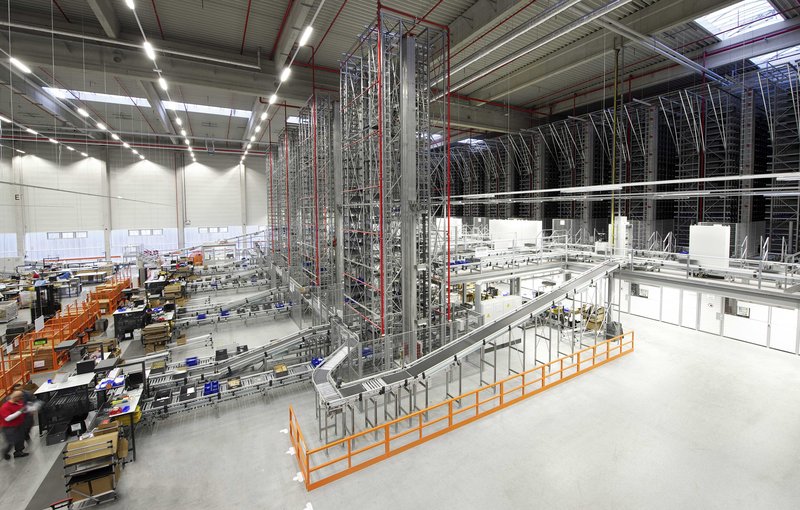

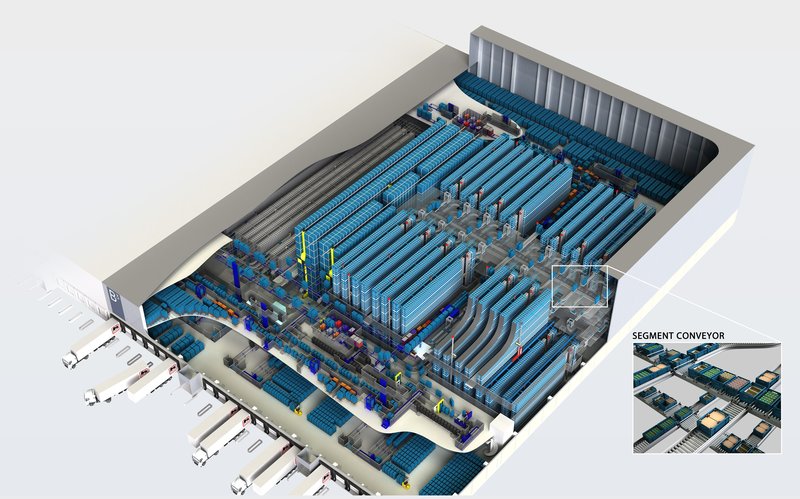

Switzerland is known throughout the world: For its stable economic system, for the quality, design, and precision of the watches manufactured there, the impressive mountain scenery, and the success of its winter sports athletes. Switzerland also stands for innovation. This innovative strength is also evident in the omni-channel distribution center of Migros Verteilbetrieb AG (MVB) in Neuendorf (near Basel), which, according to MVB Project Manager Alexander Schweizer, belongs to the “unmitigated Champions League” and is one of the most dynamic logistics centers in the world.

It was designed and implemented by the logistics lifetime partner WITRON. The main building, which houses the near- and non-food area, supplies more than 700 stores and many thousands of home shopping customers from a range of 100,000+ items per year. On a peak day, WITRON’s OPM, AIO, CPS systems pick more than 470,000 cases.